ComWinTop

Regional Water Leakage Detector, Detection Controller with 5m sensing cable

Couldn't load pickup availability

Please notice: All prices are untaxed!

Regional leak detection

controller

Product introduction

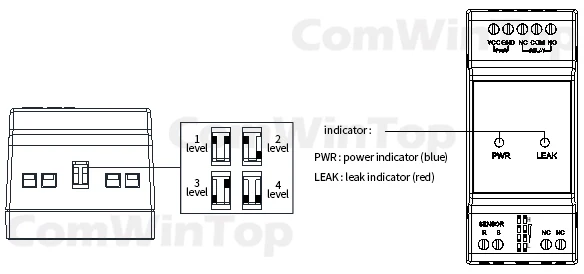

CWT-YJ-ML-S regional leak detection controller is a liquid leak detection equipment with simple operation and high-cost performance. Different sensing sensitivities can be selected through the DIP switch on the panel to adapt to different detection environments and level requirements. The relay output can be combined with various monitoring systems to achieve remote monitoring.

Application

CWT-YJ-ML-S is suitable for IDC computer rooms, data centers, smart buildings, libraries, museums, warehouses and other places where there is a risk of liquid leakage.

Features

Stable and reliable |

CWT-YJ-ML-S controllers all use industrial-grade electronic components, which can not only ensure high sensitivity during detection, but also reduce false alarms caused by various external factors. It adopts electromagnetic compatibility design and has anti-surge, anti-static, anti-EFT and other protection functions. |

Adaptable |

There is a DIP switch on the controller panel. Users can select different sensing sensitivities according to the level requirements of the detection environment (the adjustment range is within 1-20cm of the cable length). |

|

Simple and easy to use |

CWT-YJ-ML-S controller is suitable for standard industrial modules and DIN rail installation. All on-site wiring can be easily completed through terminal blocks. When a leak occurs, the relay will act and the leak indicator will light up. After the danger is eliminated, the controller will automatically return to normal state., no manual on-site operation is required. |

Local sound and light alarm |

When the controller detects liquid leakage, the LED leakage indicator lights up and the internal buzzer sounds alarm. |

Specification

Sensing performance |

Response time |

≤1s |

Detection distance |

500m |

|

Working environment |

Operating temperature |

-40℃~70℃ |

Working humidity |

0~95%RH (no condensation) |

|

Power |

Supply voltage |

DC 9~30V, recommend DC 12V |

Power consumption |

<1W |

|

Relay output |

Contact type |

One set, normally closed (NC), normally open (NO) |

load capacity |

120VAC/2A,24VDC/2A |

|

EMC protection level |

static electricity |

Contact discharge ±4KV, Air discharge ±4KV |

surge |

±1KV |

|

EFT |

±1KV |

Size

(Unit: mm, error ±0.5mm)

Button and indicator

Non-locating

leak sensing cable

Product introduction

The Non-locating leakage sensing cable is suitable for various places with the risk of liquid leakage. It can be connected with most leakage alarm hosts to form a leakage detection system. It has high detection sensitivity and fast and reliable response. The sensing cable is made of two lightweight high-density polyethylene wires pressed around a spiral central axis. Compared with parallel structure induction lines, the spiral structure can reduce environmental electromagnetic interference and false alarm rates, and also greatly improves the strength and safety of the cable service life.

Application

It is suitable for various places with risk of liquid leakage such as IDC computer rooms, libraries, museums, warehouses, etc.

Features

The patented spiral structure design of the cable can not only reduce environmental electromagnetic interference and reduce the false alarm rate, but also greatly improve the strength and service life of the cable.

The sensing cable adopts a two-core wire design and is universally applicable to any leak detection system based on the short-circuit principle. It can be used with non-locating series leakage controllers.

The sensing cable has a plastic connector with a unique waterproof structure, which facilitates cascading to expand the detection range. Various length specifications are available to meet various detection range needs.

The cable is highly flexible and can be installed in complex, curved pipes and other on-site environments.

Specifications

Items |

Specification |

Cable diameter |

Ø6.0mm |

Cable wire external resistance |

≤0.1Ω/m |

Cable weight |

28g/m±2 g/m |

Cable color (skeleton) |

yellow |

skeleton material |

PVC |

Operating temperature |

-20℃~75℃ |

Flammability rating |

Refer to UL 94-2017 standard and comply with V0 level |

Working principle

When liquid comes into contact with the sensing cable, the inner core wires of the two sensing cables are connected to the liquid, forming a loop. The leakage controller detects the leakage and sends out an alarm signal.

Introduce your content

Answer your customers' common questions

List a frequently asked question

Then provide an answer that will help your customer make an informed purchase.